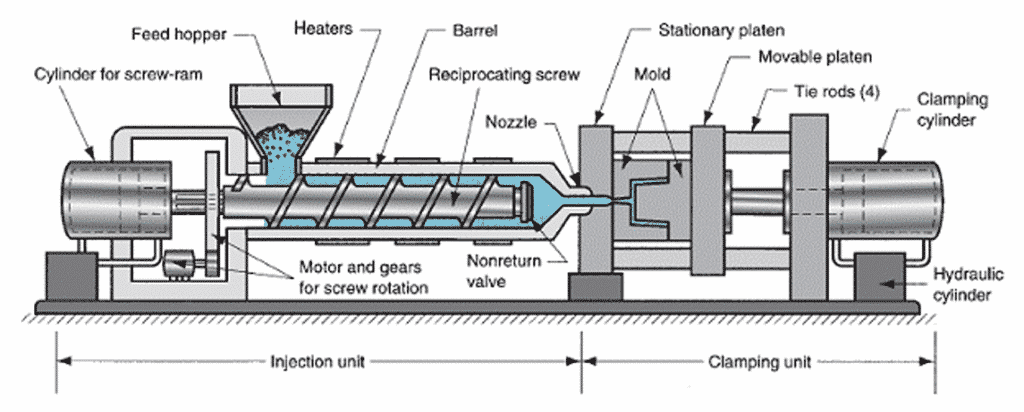

As fabricating steel molds for plastic injection molding is quite expensive, the cost of the steel molds is offset by the low cost-per-part offered by the injection molding process. Design flexibility, low part cost, a wide range of materials and finishing options, and the expansive customization techniques have made injection molding one of the best manufacturing processes available for engineers worldwide. As a matter of fact, the global injection molded plastics market size was valued at a breathtaking $258.2 billion in 2019, which clearly shows how big and important injection molding has become for manufacturers in recent years. Even though the whole injection molding machinery and technology is moving forward at a very fast pace, fundamentally the very process has not changed since its inception. It’s simple as heating plastic to a molten state and injecting it into a cavity. The parts of the process which breathtakingly evolve are the machinery design, scientific understanding of plastic flow, and makers’ ability to control nearly every detail of the molding process. If you closely watch how a machine operates, you may only see a mold opening and closing and new parts coming out. Still, there is considerably more going on inside the machines to make sure parts come out the same every time. In this article, we offer you a quick rundown of the process, starting with a closed mold.

Mold Close

Within the most simple application, the molding machine closes the mold and applies clamp pressure. As a safety check, the machine is monitoring how much pressure it’s applying in the given time. Depending on the machine, there may also be a closing profile, where the machine operator sets varying speeds as the mold closes. This setting is more used when molds become more complicated. In advanced applications, molds may have actions, hydraulics, over-molded inserts, and unscrewing operations that work together with the mold close operation. The most important thing is to find a balance between fast closing, time, and safety. In most cases, it’s just not worth pushing the machine to its edge to pick up a couple of extra fractions of a second.

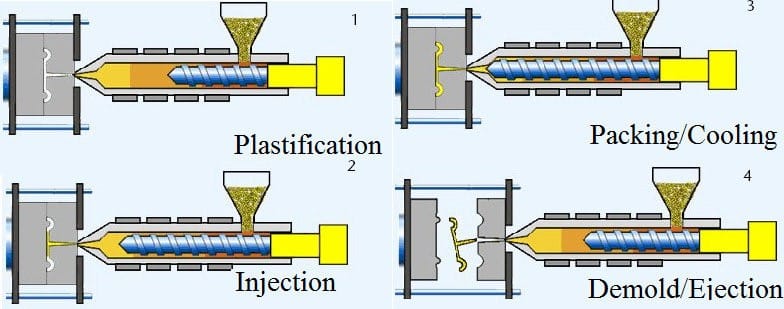

Injection

During injection time, the machine screw moves forward, pushing molten plastic out of the barrel and into the mold cavities. Be aware that injecting too fast or too slow can cause a myriad of part defects. Even though this process seems pretty simple, it goes much deeper than that. When needed, a maker can slow down or speed up the screw speed when plastic reaches specific areas on the part. This high level of control can make all the difference in producing high-quality, consistent products.

Photo from Research Gate One of the most important aspects of injection is when to move to the stage of the pack and hold. Also known as the transfer point, this is where the particular operator is switching from putting a volume of plastic into the mold at a specific speed to holding a specific amount of pressure for a period of time. The general rule is to fill the cavities nearly full during the injection phase. The most advanced and accurate way is to have cavity pressure sensors, which will control the molding machine on each cycle via feedback inside the mold. It requires an external control system, and each mold requires extra components.

Pack And Hold

When the part is mostly full, it’s the right time to pack the part out the rest of the way and hold material pressure until the gates freeze. It’s very important that the gate design and size are correctly matched to the part. After that, the gates need to cool down enough to isolate the part from the feed system.

Cooling And Plasticizing

Right after the pack and hold stage, the part is filled out but is still too hot to be removed from the mold. The cooling down is simply time allotted for the mold to absorb heat from the plastic part. As this part goes on, the molding machine begins recharging material in the barrel to prepare for the next cycle. The screw once again starts spinning and conveys raw material down the barrel. As the plastic material moves, it pushes the screw backward. The most important variables used for plasticizing are screw RPM and backpressure. RPM is really the speed the screw rotates and the back pressure is the amount of resistance the machinery applies against the movement of the screw. Having high RPM and back pressure can mix material better and raise the temperature of the plastic. Once the cooling phase is done and the machine is ready for the next cycle, the mold is opened.

Finished Part Ejection

When the mold is opened, the parts need to be removed. This stage may be a single pulse of molds ejection system, or it may need various ejection strokes and advanced robotics. If the machine works with robotics, the robot will signal the molding machine to start the ejection process. When the parts are removed from the mold, we have completed a full cycle of the injection molding process. The speed of each cycle is decided by mold operation and part design. However, the entire process may take place in seconds, or over a minute depending on the complexity of the job. Other variables will include preparation of the molding material, mold cooling temperature, barrel temperatures, integrated robotics, hot runner system control, and other changeable components of the molding machine.

Photo from XCentric The main challenge with injection molding is balancing all aspects and factors to produce high-quality consistent parts. Some minor changes in one phase may cause implications of another phrase of the process. The good thing for engineers is that the technology and machinery that’s available to us can make the process very precise and consistent when used properly.